Cairns Printing Services

In addition to our extensive list of products and services that are available to order online, Copy Shop Print & Signs also offers a range of Cairns printing services to assist businesses with their printing needs.

Lamination ensures the print is protected from UV light when used outdoors and makes the surface wipeable.

Floor displays are laminated to add a non-slip and hard wearing surface.

Textured coatings can add a unique feel to your printing.

- Scan to Print / Scan to PDF / Scan to Editable Text using OCR / Scan to Email or USB

- Do you have documents, drawings or photos you would like saved or copied?

- Do you have printed text that you would like in an editable format, for you to change or add to?

- Do you need to send printed document by email?

- Or do you simply want to keep a copy on file?

We can do it all. From large format plans to tiny photos, we can scan them into the format you require.

Plastic Spiral Binding

This is an economical way to present your document. Your binding includes a plastic front cover in either gloss or matt finish with a colour leather grain card stock backing.

Wire Binding

For the ultimate finish our wire binding comes in a variety of different sizes. Standard coil colours are white and black other colours are available on request. Your binding includes a plastic front cover in either gloss or matt finish with a colour leather grain card stock banking.

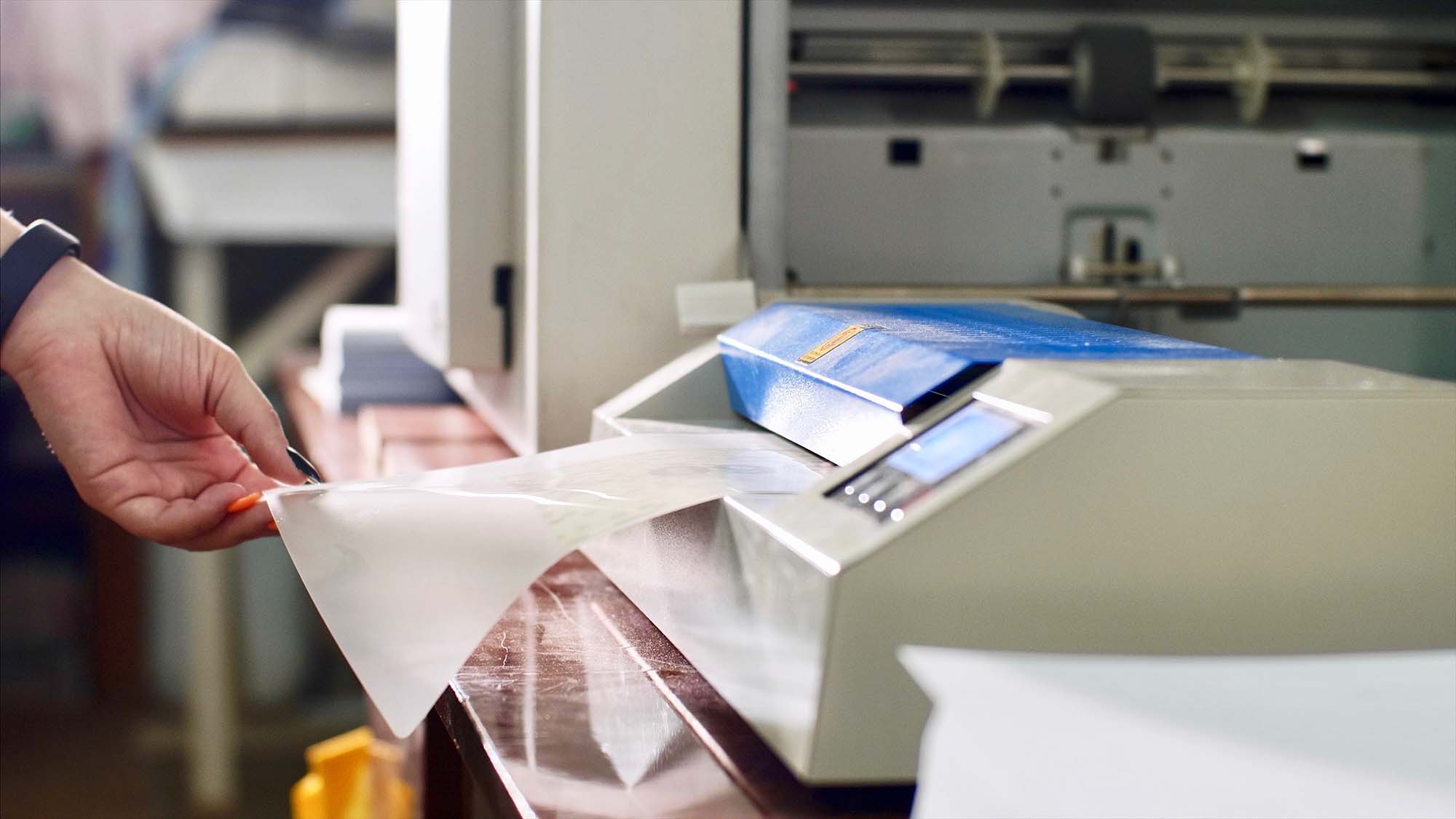

The application of plastic film lamination to display posters, signs and boards they can be single sided or double sided, hot or cold.

Plastic film lamination protects originals, enhances graphics and signage with a wide range of surface finishes. It can also increase rigidity for handling and reduce UV fading for longer life of printedmaterial and inkjet prints.

Hot or Cold Lamination?

Both methods have their advantages and disadvantages determined by the kind of picture and printing process to be protected or enhanced and based on findings and experience in practice. Neither can be guaranteed because of the high number of factors that can effect the final result. Heat can often effect the material being laminated.

We recommend the following:

- Hot lamination for standard offset, electrostatic, laser printed or photocopied material.

- Cold lamination process for all printed materials, especially for standard inkjet, wide format inkjet, thermal wax prints and photographs. Being single sided cold lamination can be applied to images mounted onto boards and thick substrates.

Hot Roll Lamination

Often called encapsulation or heat sealing, applies heat activated film to both sides of the poster Seals the poster and adds rigidity. Least expensive. Limited types of films available. The greater the thickness the more rigid the laminate.

Cold Lamination

Consists of a pressure sensitive film applied to the front of the print. Can also be applied to the back where encapsulation is required. Gives superior clarity, is available in non reflective finishes. Is generally always used on the face of mounted prints.

- Prior to laminating, prints can be mounted to a wide range of backing material ranging from card, MDF board, foam board, corflute, acrylics and other sophisticated plastics.

- We can advise the best option for your application and we have the latest technology to ensure blemish free results.

- We can laminate small prints (up to A3) while you wait, great for menus, presentations, cards and small signage.

Other Cairns Printing Services

If you’ve got a custom job or looking for any other Cairns printing services, our friendly team is here to help. Get in touch with us today to assist with your next project.

Order Printing Online

It’s easy to order your printing online! We offer a large range of printing services online, so you can browse our products, submit your job and pay online.

Head to our online store to order online 24/7.